Have you ever noticed a faint red light near your Android phone’s camera? This seemingly innocuous glow can spark curiosity and concern. Worry not, for this article delves …

Some people notice that their Android phone has app manager apps installed on their phone, and more specifically, the Meta app manager app which not a lot of …

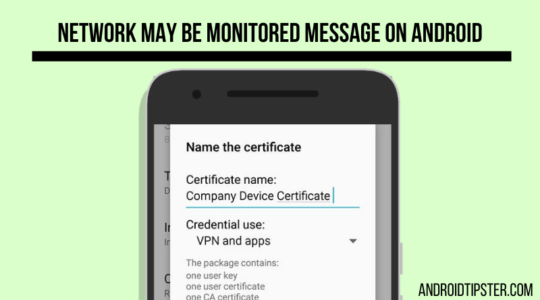

Android is one of the most used and popular mobile operating systems in the world. It is full of features. However, there are some features that might make …

If you are using an android smartphone, you will receive notifications for upgrading the software from time to time. If you go through it, the android version of …

As gaming PCs become more and more affordable, the possibilities of the kind of specs and features you can get in a PC under $1,000 are just endless. …

Wi-Fi networks are everywhere and with the touch of a button, we can connect our android devices to such networks. We all know that it is possible to …

Nowadays smartphones come packed with a number of different sensors. All of those sensors are very useful under different circumstances. One of those sensors is the ‘Gyroscope’ sensor. …

Quick Solution You can downgrade to older Android versions ( older than Lollipop ) You can use power saver mode to save on battery life You can try …

Android operating system is the most used and popular smartphone operating system in the world right now. People like android because of its customizability and huge collection of …

Music is the universal language. And we usually listen to music on our smartphones nowadays. There are many music player apps out there with various features and functionalities. …